Testing Ecosystem

Berkeley Lab User Facilities Integration

FLEXLAB® is part of a testing ecosystem along with other user facilities at Berkeley Lab, resulting in an extremely comprehensive testing platform. Often, FLEXLAB can be the last stop on a project.

For example, after performance testing an individual system in our Appliance Test Chambers, users can take that data and apply it to FLEXLAB experiments for further testing, comparison and results.

To support rapid adoption of Distributed Energy Resources (DERs) FLEXLAB is useful in many other areas, including:

- energy storage

- vehicle charging

- bidirectional EV testing

- cybersecurity

- DER protocols testing

The FLEXLAB team can help develop and test controls at the end use scale and integrate with energy storage and other DERs.

Our capabilities span the spectrum, from design to test, equipment to a building zone, buildings to gird. Let FLEXLAB be your last stop before hitting the market.

Buildings

The Building Technology and Urban Systems Division at Berkeley Lab has an extensive array of testing capabilities for material characterization and performance monitoring of a wide range of building technologies.

Whole Building

Whole Building

- Berkeley Lab offers FLEXLAB®, a set of testbeds and simulation platforms for research, development, and demonstration of low energy building technologies, control systems, and building systems integration.

Please visit: flexlab.lbl.gov

Lighting

Lighting

Our Lighting Systems Test Facilities aid research that improves the energy efficiency of lighting systems. For more information: facades.lbl.gov/lighting-systems-laboratory

- The Gonio-Photometer measures illuminance from each portion of a lamp or fixture. Find out more at: windows.lbl.gov/large-goniometer

- Spectro Radiometer: Measures the light output of a light source at each wavelength.

Windows & Envelope Materials

Windows & Envelope Materials

- Advanced Windows Test Facility: Tests new window technologies for energy savings and occupant comfort. This multi-room laboratory simulates real-world office spaces and measures the performance of commercially-available and prototype window systems such as electrochromic windows and automatically controlled shutters and blinds.

Please visit: facades.lbl.gov/advanced-windows-testbed

Solar-optical Properties Laboratory

Solar-optical Properties Laboratory

The Solar-optical properties Laboratory has a complete set of instruments designed to characterize the detailed radiometric and optical properties of window glazing and shading materials. Find out more at: windows.lbl.gov/solar-optical-properties-laboratory

- Photo-Goniometer: Measures light transmission and reflection of light-emitting, light-scattering, and light-redirecting materials. For more information: windows.lbl.gov/large-goniometer

- Spectro Goniometer: Measures angle-resolved scattering versus wavelength. Find out more at: windows.lbl.gov/spectro-goniometer

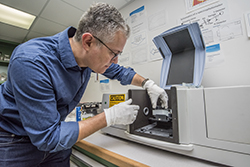

Material Characterization

Material Characterization

- Dektak 150 Surface Profiler: Measures the thickness and deposition rates of thin films grown in our coating lab.

- Pelletron: An electrostatic ion accelerator made for ion beam analysis of materials.

Thermography and Heat Transfer

- Thermal testing facilities at Berkeley Lab serve to assure credibility of models and software tools and to determine thermal performance of new products and technologies. Fore more information: windows.lbl.gov/thermal-properties-laboratory

- Infrared Thermography Laboratory: A platform for conducting detailed experiments on the thermal performance of windows and other insulated systems. For more information: facades.lbl.gov/infrared-thermography-laboratory

- Mobile Window Thermal Test Facility (MoWITT): Contains two side-by-side calorimetric test chambers for testing the thermal performance of window and wall elements under actual outdoor conditions. Find out more at: facades.lbl.gov/mowitt-mobile-window-thermal-test-facility

Thin Film & Deposition Systems

- Coating Lab: Contains chambers for growing thin film window coatings.

- Plasma Applications Coating Lab: Contains chambers for growing thin film window coatings. For more information: facades.lbl.gov/plasma-assisted-deposition-laboratory

- Solar Control Thin Films Laboratory: Develops novel thin film coatings, deposition technologies, and device systems for next-generation, energy-efficient windows.

Energy Analysis

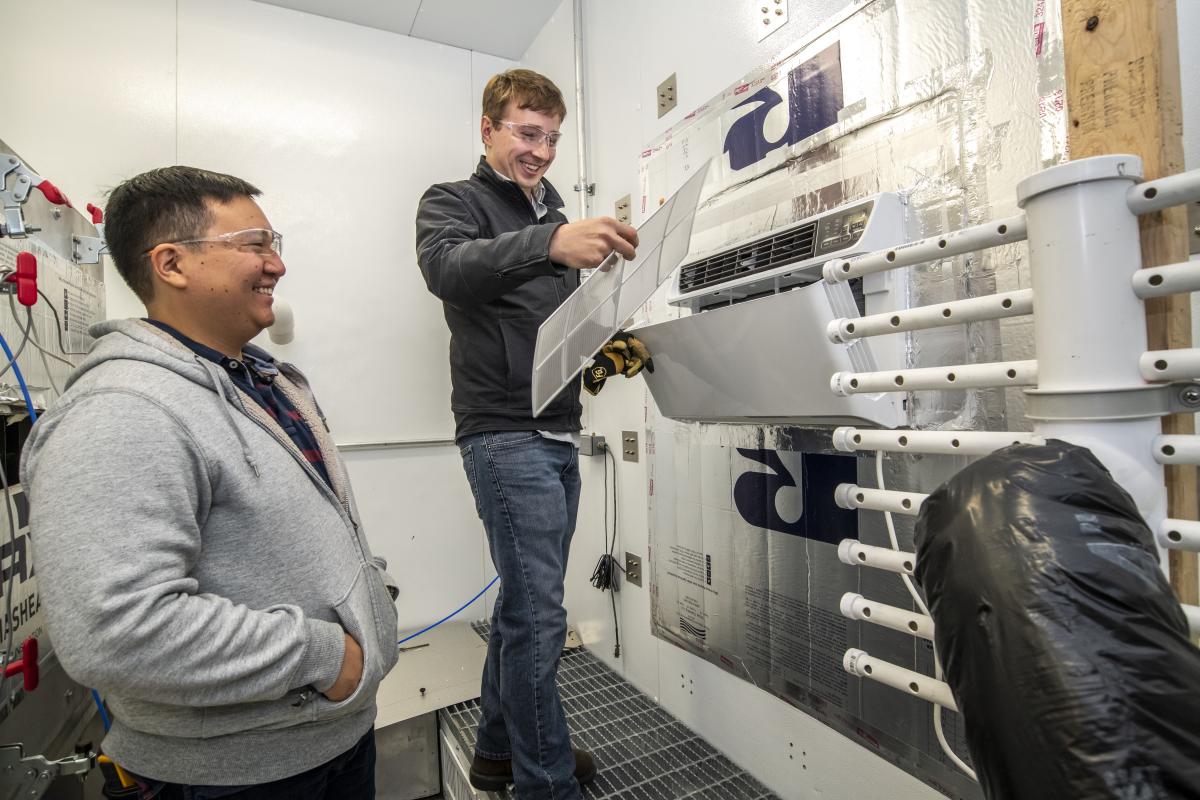

Balanced Ambient Calorimeter Test Chamber

Balanced Ambient Calorimeter Test Chamber

The Balanced Ambient Calorimeter Test Chamber's primary purpose is to evaluate the performance of room air conditioners (split, window, or wall-type), packaged terminal air conditioners and packaged terminal heat pumps in the cooling capacity range of 6,000 to 42,000 Btu/h (½ to 3 ½ rated tons). It consists of side-by-side indoor and outdoor chambers with temperature, humidity and air flow controlled independently. Both the indoor room and the outdoor room are surrounded by an annular space which independently maintains the same temperature and humidity as the rooms it surrounds. The Test Chamber is designed to maintain a single set of operating conditions and is able to maintain conditions within the following dry bulb and web bulb temperature ranges: indoor = 45°F to 100°F DB; 43°F to 79°F WB; outdoor = 10°F to 120°F DB; 40°F to 81°F WB.

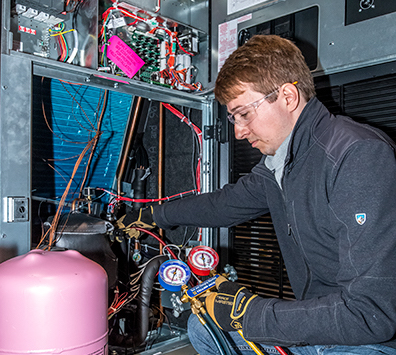

Psychrometric Test Chamber

Psychrometric Test Chamber

The Psychrometric Test Chamber's primary purpose is to evaluate the performance of central air conditioners and heat pumps with cooling capacity in range of 6,000 to 90,000 Btu/h (0.5 to 7.5 rated tons), and with heating capacity in range of 6,000 to 60,000 (0.5 to 5 ton rated). It consists of side-by-side indoor and outdoor chambers with temperature, humidity and air flow controlled independently.

The Test Chamber is designed to maintain a single set of operating conditions and is able to maintain conditions within the following dry bulb and web bulb temperature ranges:

Indoor = 45°F to 100°F DB; 43°F to 85°F WB

Outdoor = -20°F to 120°F DB; 35°F to 90.5°F WB.

Refrigerator Test Chamber

Refrigerator Test Chamber

The Refrigerator Test Chamber's primary purpose is to evaluate the performance of household refrigerator-freezers, refrigerators, freezers, wine chillers and ice makers. It is a temperature- and humidity-controlled environmental room that provides controlled environmental conditions.

The Test Chamber is designed to maintain a single point operating condition and is able to maintain dry bulb temperatures in the range of 40°F to 120°F and humidity conditions in the range of 30% to 95%. It has the capability of testing four refrigeration units simultaneously at a single operating condition.

Indoor Air Quality Laboratory Facilities

Indoor Air Quality Laboratory Facilities

The Indoor Environment Group has a portfolio of unique chamber facilities and state-of-the-art analytical systems for measuring the emission rates of pollutants from building materials and products, evaluating the performance of prototype air cleaning and sensor technologies, and evaluating and studying how indoor environmental conditions affect people’s acute health symptoms and work performance. These facilities and analytical systems are used in studies for industry to evaluate prototype technologies as well as in research supported by governmental organizations.

Range Hood Test Facility

Range Hood Test Facility

The Indoor Environment Group has a unique laboratory, plus associated protocols and instrumentation systems designed to characterize the performance of residential range hoods. The facility enables characterization of pollutant emissions associated with cooking devices and cooking activities. Performance measures include airflow, sound pressure and pollutant capture efficiency.

Stove Testing Facility

Stove Testing Facility

The Indoor Environment Group has a unique testing facility for evaluating pollutant emissions and fuel consumption of stoves used in the developing world.

The facility is used to evaluate prototype stove designs and to compare existing products. This facility has been used to test many stoves, including wood, charcoal, and coal cooking and heating stoves.

Additional Berkeley Lab Facilities

In addition to the above Division-specific facilities, Berkeley Lab is home to a number of world-class facilities, including:

- Advanced Light Source (ALS): A particle accelerator that generates bright beams of x-rays for scientific research in biology, chemistry, physics, materials, energy, and environmental science. This national user facility attracts more than 2000 researchers and students annually from around the world.

Please visit: als.lbl.gov

- National Energy Research Scientific Computing Center (NERSC): One of the largest facilities in the world devoted to providing computational resources, NERSC is a world leader in accelerating scientific discovery through computation. NERSC is the primary scientific computing facility for the Office of Science in the U.S. Department of Energy.

For more information: www.nersc.gov and www.energy.gov